Aluminum is popular for various applications due to its lightweight, strength, and corrosion resistance. The mechanical properties of aluminum can be altered using several processes, including work hardening and adding alloying elements; however, one of the most common ways of altering certain grades of aluminum is through tempering.

Since the tempering process can have such a significant effect on aluminum alloys, it’s crucial to understand the various aluminum temper designations and what they mean. This is critical in ensuring you choose the correct material and preventing failures or fractures.

What Are Temper Designations for Aluminum?

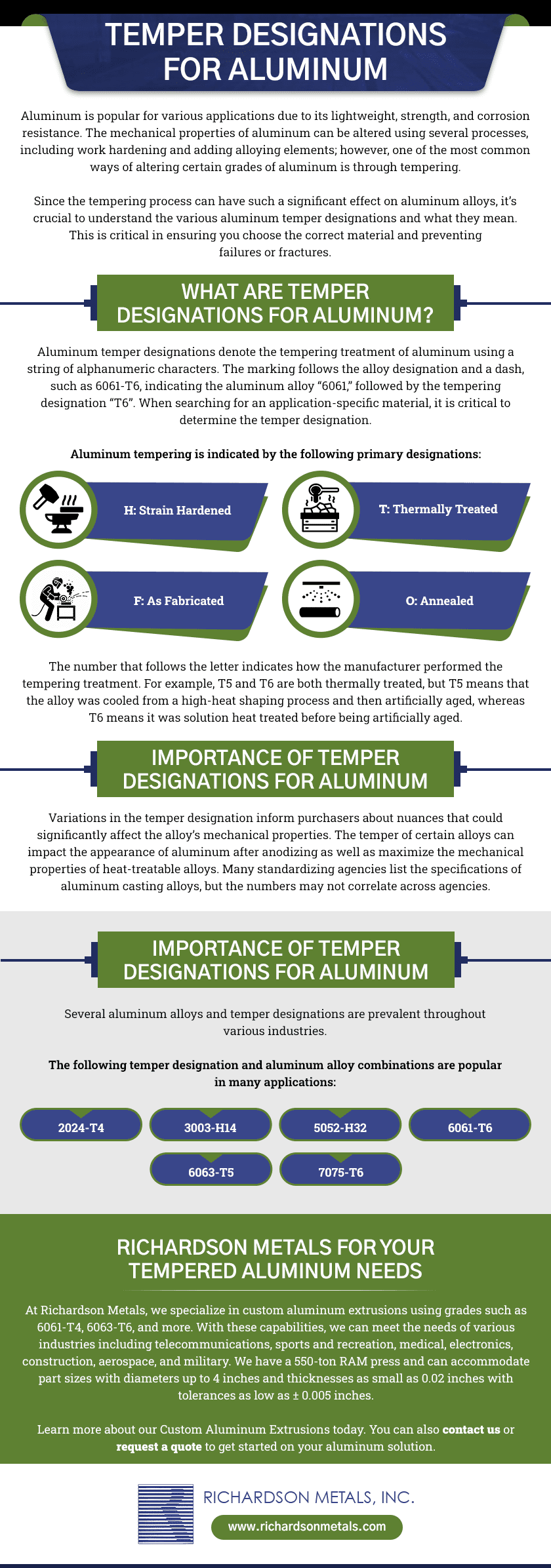

Aluminum temper designations denote the tempering treatment of aluminum using a string of alphanumeric characters. The marking follows the alloy designation and a dash, such as 6061-T6, indicating the aluminum alloy “6061,” followed by the tempering designation “T6”. When searching for an application-specific material, it is critical to determine the temper designation. Aluminum tempering is indicated by the following primary designations:

- H: Strain hardened

- T: Thermally treated

- F: As fabricated

- O: Annealed

The number that follows the letter indicates how the manufacturer performed the tempering treatment. For example, T5 and T6 are both thermally treated, but T5 means that the alloy was cooled from a high-heat shaping process and then artificially aged, whereas T6 means it was solution heat treated before being artificially aged.

Importance of Temper Designations for Aluminum

Variations in the temper designation inform purchasers about nuances that could significantly affect the alloy’s mechanical properties. The temper of certain alloys can impact the appearance of aluminum after anodizing as well as maximize the mechanical properties of heat-treatable alloys. Many standardizing agencies list the specifications of aluminum casting alloys, but the numbers may not correlate across agencies.

Common Aluminum Temper Designation Applications

Several aluminum alloys and temper designations are prevalent throughout various industries. The following temper designation and aluminum alloy combinations are popular in many applications:

- 2024-T4: Screw machine products, wheels, hardware, fasteners, and aircraft structures

- 3003-H14: Pipes, pressure vessels, litho sheet, trim, tanks, and equipment for food and chemical handling

- 5052-H32: Rivets, wire, lighting, appliances, transportation, fuel tanks, and oil and fuel lines in aircraft

- 6061-T6: Valve parts, valves, appliance fittings, hydraulic pistons, brake pistons, magneto parts, hinge pins, general and decorative hardware, electrical connectors and fittings, marine hardware and fittings, couplings, camera lens mounts, and aircraft fittings

- 6063-T5: Transportation, irrigation pipes, architectural extrusions, furniture, railings, and pipes

- 7075-T6: ATV sprockets, defense and aerospace parts, aircraft, keys, worm gears, regulating valve components, missile parts, gears and meter shafts, fuse parts, shafts, and aircraft fittings

Richardson Metals for Your Tempered Aluminum Needs

Aluminum tempering designations are critical in understanding the mechanical properties of various aluminum alloys. Knowing these designations ensures you choose the right aluminum alloy for your particular project.

At Richardson Metals, we specialize in custom aluminum extrusions using grades such as 6061-T4, 6063-T6, and more. With these capabilities, we can meet the needs of various industries including telecommunications, sports and recreation, medical, electronics, construction, aerospace, and military. We have a 550-ton RAM press and can accommodate part sizes with diameters up to 4 inches and thicknesses as small as 0.02 inches with tolerances as low as ± 0.005 inches.

Learn more about our Custom Aluminum Extrusions today. You can also contact us or request a quote to get started on your aluminum solution.