Step-by-Step Aluminum Extrusion Process

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into profiles with a uniform cross-sectional shape. It is a highly versatile and cost-effective method to create complex and customized metal parts and structures. Hence, this method is widely used in the construction, automotive, aerospace, electronics, transportation, and consumer goods industries.

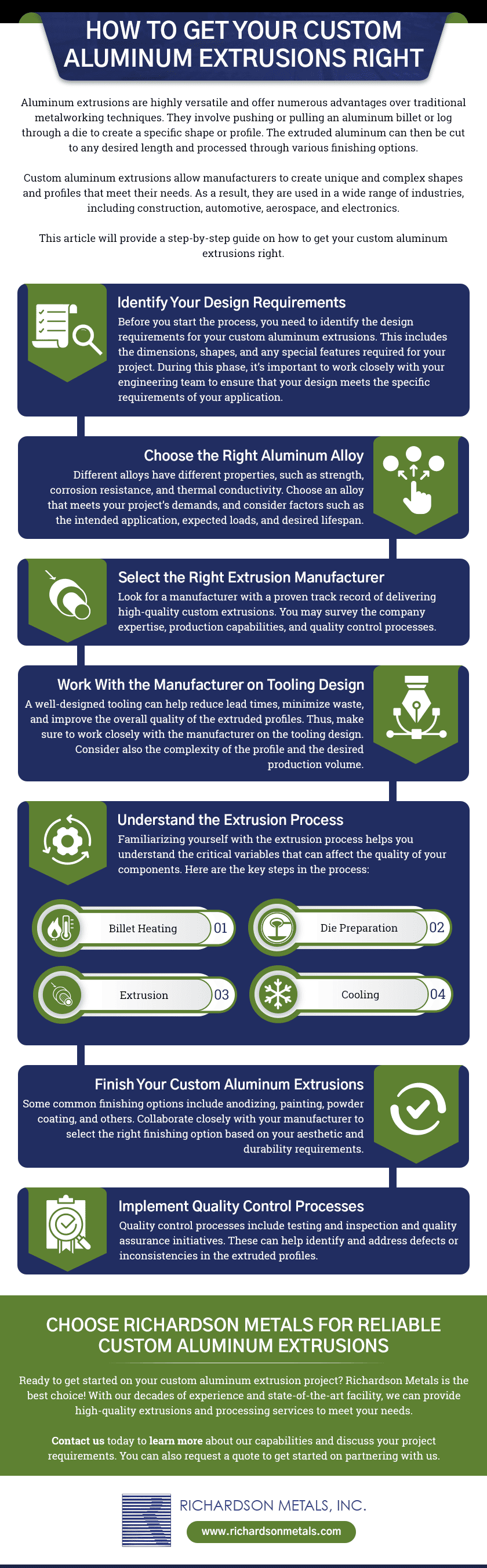

The aluminum extrusion process involves several steps that transform a billet into a finished extruded profile. Here is an overview:

Step 1: Preparing the Billet

Billet preparation is the initial stage, where a suitable billet is selected and prepared for extrusion. It is often made from an aluminum alloy and is carefully cut into specific lengths based on the requirements. Then, the billet is heated to the extrusion temperature, making it more malleable for the next step. Homogenization may be performed to ensure uniform alloy composition.

Step 2: Setting Up the Extrusion Press

The setup process includes preparing the extrusion die, which is a specially designed metal component that determines the final extruded profile’s shape. It is then inspected and cleaned to ensure its proper functioning. Next, the press is prepared by adjusting various parameters such as the hydraulic system, temperature controls, and pressure settings. Finally, the heated billet is loaded into the press.

Step 3: Preheating the Container

Preheating the container minimizes heat loss and maintains the temperature of the billet throughout the process. The preheating temperature must be controlled and monitored to align with the desired temperature. This step allows the thermal energy to be absorbed and retained, creating a conducive environment for the extrusion operation.

Step 4: Extruding the Billet

Ram extrusion is the application of intense pressure using a ram to propel the heated billet through the die. As pressure is applied, the aluminum billet undergoes plastic deformation and takes on the form of the die opening. The pressure and speed of the ram are precisely controlled to ensure uniform flow and maintain the desired dimensions and surface quality.

Step 5: Cooling and Handling

The extruded profile is cooled using either water or air, depending on the specific requirements of the alloy. Cooling the profile helps harden it, stabilize its structure, and improve its mechanical properties. Proper cooling also aids in setting the desired metallurgical properties of the alloy, enhancing its strength and durability.

After the extruded profile has undergone adequate cooling and solidification, it is carefully handled and transferred to subsequent post-processing stages. These may involve cutting, machining, surface treatment, or additional heat treatments.

Step 6: Stretching and Cutting

The profile undergoes stretching to improve its straightness and dimensional accuracy. This process typically applies controlled tension, either manually or with the help of specialized stretching equipment. Then, it is cut into desired lengths, which can be performed through sawing, shearing, or precision cutting techniques.

Step 7: Quality Control Checking

Quality control measures are implemented to assess the extruded profiles for defects, dimensional accuracy, surface finish, and mechanical properties. Inspection techniques are utilized to identify any issues or deviations from the desired specifications. Any profiles that fail to meet the quality criteria are either rejected, reworked, or subjected to further analysis to determine the cause of the nonconformity.

Choose Richardson Metals for Custom Aluminum Extrusions

At Richardson Metals, we pride ourselves on our commitment to excellence in producing custom aluminum extrusions. We use premium-grade materials to ensure our extruded products’ highest quality and performance. We also guarantee that every extrusion that leaves our facility meets the strictest industry standards.

Contact us today to learn more about our capabilities! You can also request a quote now to receive a competitive pricing estimate.