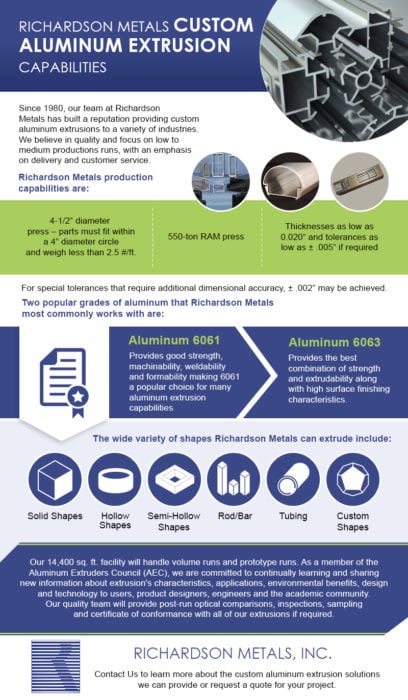

The two most popular grades of aluminum that Richardson Metals commonly extrude are:

- ALUMINUM 6061 – Provides good strength, machinability, weldability, and formability making 6061 a popular choice for many aluminum extrusion applications.

- ALUMINUM 6063 – Provides the best combination of strength and extrudability along with high surface finishing characteristics.

Aluminum extrusion is a highly versatile manufacturing process that creates many different parts and products. At Richardson Metals, our aluminum extrusions find application in a diverse set of industries, including the following:

- Aerospace and Military Aluminum offers a high strength-to-weight ratio, suitability for use in low temperatures, and minimal maintenance requirements, all of which make it ideal for use in aerospace and military operations. Aluminum extrusions are used as components in many different devices, equipment, and systems, such as those found in aircraft, the International Space Station (ISS), and military and hospital field sites.

- Construction Aluminum extrusions serve many functions in buildings. In addition to providing structural support in normal and extreme conditions, they can improve both functional and aesthetic qualities. For example, when designed and constructed carefully, they can decrease energy consumption or decorate interior and exterior areas.

- Electronics Aluminum is commonly used for components in electronic devices due to its formability, thermal and electrical conductivity, and non-magnetic properties. Some of the electronic products in which aluminum extrusion are commonly found include cell phones, computers and laptops, electronic chassis, racks, and housings, motors, and power distribution systems.

- Medical Aluminum is ideal for use in the manufacture of components for medical equipment, such as hospital beds and testing devices. Additionally, aluminum extrusions can be made to tight tolerances, which allows them to meet the industry’s strict standards.

- Sports and Recreation Aluminum demonstrates a high strength-to-weight ratio, meaning it is sturdy without adding a significant amount of weight. It is also highly formability, accommodating a variety of complex and intricate part designs. These qualities make it suitable for sports and other recreational equipment, such as bicycle frames, skates and skateboard hardware, boats, and more.

- Telecommunications Aluminum and aluminum alloys play an important role in creating the hardware and infrastructure for the telecommunications industry. The metal is light-which reduces transportation and installation costs—and conducts electricity well. Common applications for aluminum extrusions in the telecommunications industry include cables and satellite parts.