Tailoring Success: The Art of Custom Aluminum Extrusions at Richardson Metals

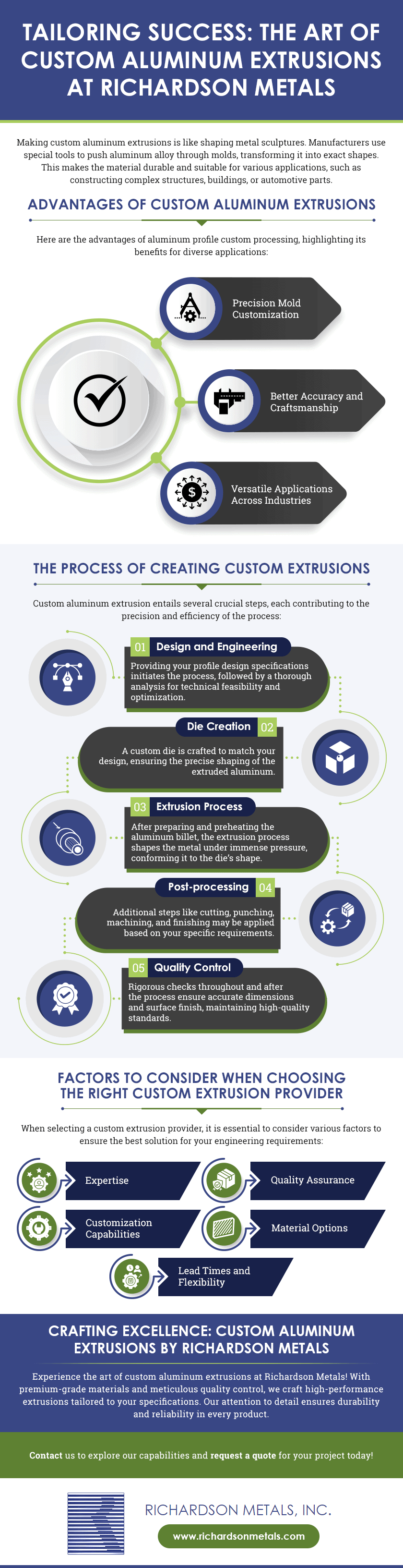

Leave a CommentMaking custom aluminum extrusions is like shaping metal sculptures. Manufacturers use special tools to push aluminum alloy through molds, transforming it into exact shapes. This makes the material durable and suitable for various applications, such as constructing complex structures, buildings, or automotive parts.

This blog explores Richardson Metals’ mastery of custom aluminum extrusions, precisely shaping metal for diverse applications.

Advantages of Custom Aluminum Extrusions

Here are the advantages of aluminum profile custom processing, highlighting its benefits for diverse applications:

Precision Mold Customization

Custom aluminum extrusions are made with precise molds tailored to different sizes and technical standards based on specific project design requirements. This ensures that the final products are exactly as needed, with a smooth texture and refined appearance.

Better Accuracy and Craftsmanship

Creating tailor-made extrusions involves using advanced tools and methods, which guarantee accurate shaping and high-quality craftsmanship. Manufacturers carefully consider the product’s design during customization, ensuring it meets the client’s preferences and budget.

Versatile Applications Across Industries

Extruded aluminum is widely utilized in architecture, display equipment, electrical systems, and industrial applications. Additionally, it is suitable for industries that require a high strength-to-weight ratio for parts, such as transportation, aerospace, and automotive.

The Process of Creating Custom Extrusions

Custom aluminum extrusion entails several crucial steps, each contributing to the precision and efficiency of the process:

- Design and engineering: Providing your profile design specifications initiates the process, followed by a thorough analysis for technical feasibility and optimization.

- Die creation: A custom die is crafted to match your design, ensuring the precise shaping of the extruded aluminum.

- Extrusion process: After preparing and preheating the aluminum billet, the extrusion process shapes the metal under immense pressure, conforming it to the die’s shape.

- Post-processing: Additional steps like cutting, punching, machining, and finishing may be applied based on your specific requirements.

- Quality control: Rigorous checks throughout and after the process ensure accurate dimensions and surface finish, maintaining high-quality standards.

Factors To Consider When Choosing the Right Custom Extrusion Provider

When selecting a custom extrusion provider, it is essential to consider various factors to ensure the best solution for your engineering requirements:

✔ Expertise: Choose a provider with a solid track record in custom extrusion and experience with a range of materials and extrusion techniques.

✔ Quality assurance: Select a provider with robust quality control measures in place to guarantee the accuracy and consistency of their extruded products.

✔ Customization capabilities: Look for a provider that can accommodate your specific design needs and offer customized solutions tailored to your project requirements.

✔ Material options: Consider the range of materials the provider can work with and their expertise in handling different material properties and specifications.

✔ Lead times and flexibility: Assess the provider’s ability to meet your project deadlines and adapt to any changes or customizations that may arise during the extrusion process.

Crafting Excellence: Custom Aluminum Extrusions By Richardson Metals

Experience the art of custom aluminum extrusions at Richardson Metals! With premium-grade materials and meticulous quality control, we craft high-performance extrusions tailored to your specifications. Our attention to detail ensures durability and reliability in every product.

Contact us to explore our capabilities and request a quote for your project today!

Shaping the Future: Exploring the Versatility of Aluminum Extrusion Shapes

Leave a CommentAluminum extrusion is a manufacturing process that involves heating aluminum billets and pushing them through a shaped die opening. This method allows the creation of various shapes and sizes tailored to meet specific requirements. Extruded aluminum components, from beams to bars, boast exceptional versatility.

Let us explore the diverse range of shapes attainable through aluminum extrusion and their applications across multiple sectors.

Common Shapes in Aluminum Extrusion

Here are the various shapes and profiles achievable in aluminum extrusion:

Beams

Beams are vital structural components engineered to bear loads transversely to their longitudinal axis. Typically elongated and slender, their cross-sectional shape is carefully designed for optimal strength, rigidity, and overall reliability. They serve as foundational elements in construction. For instance, they reinforce chassis in automotive industries and are vital in aerospace for fuselages and wings.

The extrusion process shapes beams precisely and ensures consistency by pressing aluminum billets through dies at high temperatures to mold them into the desired form. The resulting aluminum beams boast remarkable strength-to-weight ratios, making them a preferred choice for applications necessitating robustness and lightweight properties. This flexibility facilitates seamless fabrication and installation.

Trim Caps

Trim caps are versatile profiled strips that safeguard edges and joints, fulfilling essential roles across diverse applications. They are crafted through extrusion and emerge in various shapes and sizes. The process meticulously shapes these components, guaranteeing precise dimensions and impeccable finishes.

Aluminum trim caps are durable, resistant to wear and corrosion, and provide robust protection while enhancing aesthetics. They are lightweight yet sturdy and easy to handle and install. In automotive applications, they adorn interiors and exteriors, adding sophistication to vehicle design. On the other hand, they conceal panel and structure edges in construction applications and enhance the decorative allure and visual appeal of furniture.

Rods

Rods are cylindrical solid components boasting uniform cross-sections that serve vital functions across industries. They are crafted from extruded billets, utilizing dies with circular or polygonal profiles to ensure dimensional accuracy and perfect surface finish. Rods are also known for their strength and resistance to corrosion, making them widely used in outdoor and marine settings.

Their lightweight nature and ease of machining further enhance their appeal. In construction, rods serve as reinforcement bars, fortifying structures against external forces. Additionally, they optimize engine performance in automotive engineering and act as sturdy supports for antennas, providing stable transmission and reception in electronics.

Angles

Angles are essential L-shaped structural members characterized by perpendicular legs that boost structures across various applications. In manufacturing, angles undergo extrusion through dies tailored to their specific L-shaped profiles, which ensure precise dimensions and sharp corners. This method efficiently produces custom angles that cater to diverse requirements.

Aluminum angles also boast high strength and stiffness, making them optimal for structural framing and bracing. Despite their strength, they are lightweight. Additionally, the angles have various applications: framing corners in construction, crash protection in automotive, and reinforcing structures in aerospace.

Bars

Bars represent solid metal shapes characterized by uniform cross-sections. They are frequently employed as structural elements or for support and reinforcement in diverse applications. The manufacturing process involves extruding bars from aluminum billets through dies configured with precise cross-sectional profiles, which ensure dimensional accuracy and a refined surface finish.

Aluminum bars feature exceptional strength and corrosion resistance, rendering them well-suited for outdoor and marine usage. Moreover, their lightweight nature and ease of fabrication enhance their appeal. In terms of applications, bars are widely used in construction for window and door frames. They are also utilized in the automotive for chassis reinforcement and in machinery for shafts and supports.

Get Versatile Aluminum Extrusion Shapes With Richardson Metals!

At Richardson Metals, we pride ourselves on our commitment to excellence in producing custom aluminum extrusion shapes. With a reputation for reliability, our experienced team is dedicated to meeting your unique needs, whether standard shapes or custom-designed parts. Moreover, we use premium-grade materials to ensure our extruded products’ highest quality and performance!

Contact us today to learn more about our capabilities. You can also request a quote now to receive a competitive pricing estimate.