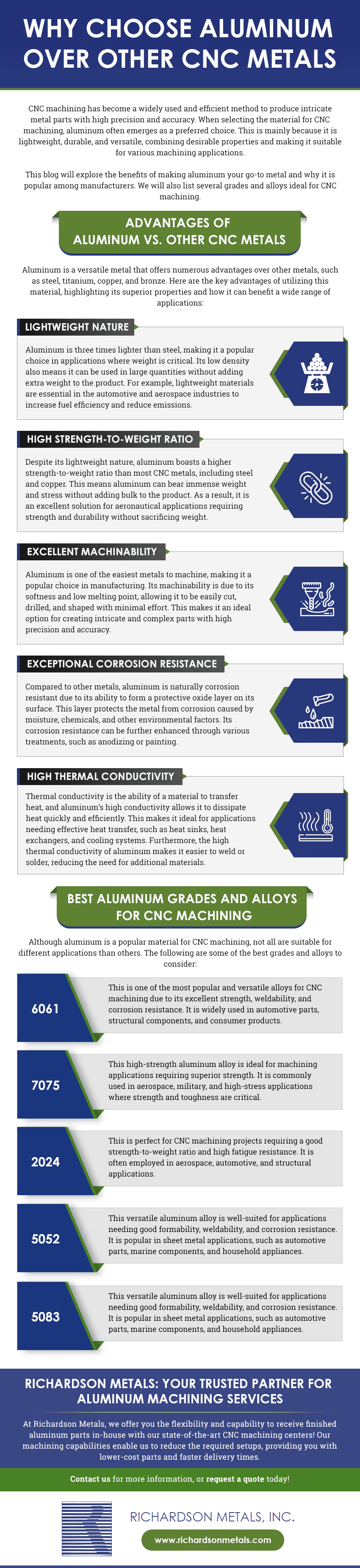

CNC machining has become a widely used and efficient method to produce intricate metal parts with high precision and accuracy. When selecting the material for CNC machining, aluminum often emerges as a preferred choice. This is mainly because it is lightweight, durable, and versatile, combining desirable properties and making it suitable for various machining applications.

This blog will explore the benefits of making aluminum your go-to metal and why it is popular among manufacturers. We will also list several grades and alloys ideal for CNC machining.

Advantages of Aluminum vs. Other CNC Metals

Aluminum is a versatile metal that offers numerous advantages over other metals, such as steel, titanium, copper, and bronze. Here are the key advantages of utilizing this material, highlighting its superior properties and how it can benefit a wide range of applications:

Lightweight Nature

Aluminum is three times lighter than steel, making it a popular choice in applications where weight is critical. Its low density also means it can be used in large quantities without adding extra weight to the product. For example, lightweight materials are essential in the automotive and aerospace industries to increase fuel efficiency and reduce emissions.

High Strength-to-Weight Ratio

Despite its lightweight nature, aluminum boasts a higher strength-to-weight ratio than most CNC metals, including steel and copper. This means aluminum can bear immense weight and stress without adding bulk to the product. As a result, it is an excellent solution for aeronautical applications requiring strength and durability without sacrificing weight.

Excellent Machinability

Aluminum is one of the easiest metals to machine, making it a popular choice in manufacturing. Its machinability is due to its softness and low melting point, allowing it to be easily cut, drilled, and shaped with minimal effort. This makes it an ideal option for creating intricate and complex parts with high precision and accuracy.

Exceptional Corrosion Resistance

Compared to other metals, aluminum is naturally corrosion-resistant due to its ability to form a protective oxide layer on its surface. This layer protects the metal from corrosion caused by moisture, chemicals, and other environmental factors. Its corrosion resistance can be further enhanced through various treatments, such as anodizing or painting.

High Thermal Conductivity

Thermal conductivity is the ability of a material to transfer heat, and aluminum’s high conductivity allows it to dissipate heat quickly and efficiently. This makes it ideal for applications needing effective heat transfer, such as heat sinks, heat exchangers, and cooling systems. Furthermore, the high thermal conductivity of aluminum makes it easier to weld or solder, reducing the need for additional materials.

Best Aluminum Grades and Alloys for CNC Machining

Although aluminum is a popular material for CNC machining, not all are suitable for different applications than others. The following are some of the best grades and alloys to consider:

- 6061:This is one of the most popular and versatile alloys for CNC machining due to its excellent strength, weldability, and corrosion resistance. It is widely used in automotive parts, structural components, and consumer products.

- 7075:This high-strength aluminum alloy is ideal for machining applications requiring superior strength. It is commonly used in aerospace, military, and high-stress applications where strength and toughness are critical.

- 2024: This is perfect for CNC machining projects requiring a good strength-to-weight ratio and high fatigue resistance. It is often employed in aerospace, automotive, and structural applications.

- 5052:This versatile aluminum alloy is well-suited for applications needing good formability, weldability, and corrosion resistance. It is popular in sheet metal applications, such as automotive parts, marine components, and household appliances.

- 5083:This marine-grade alloy offers excellent corrosion resistance, high strength, and weldability. It is used in marine applications such as boat hulls and decks due to its ability to withstand saltwater corrosion.

Richardson Metals: Your Trusted Partner for Aluminum Machining Services

At Richardson Metals, we offer you the flexibility and capability to receive finished aluminum parts in-house with our state-of-the-art CNC machining centers! Our machining capabilities enable us to reduce the required setups, providing you with lower-cost parts and faster delivery times.

Contact us for more information, or request a quote today!