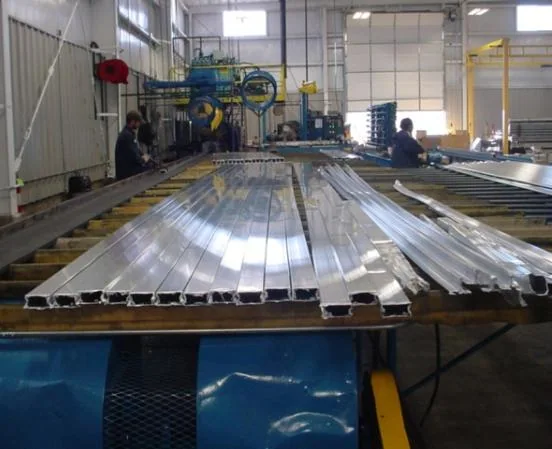

At Richardson Metals, we use strict process controls in all manufacturing processes to ensure products meet or exceed quality requirements. To minimize defects, all processes are controlled and monitored from the initial concept through the final packaging. This monitoring occurs during extrusion and stretching, as well as throughout secondary services like cutting and CNC machining. Our quality team also inspects parts during packaging to ensure they are received in the same condition in which they were sent.

Custom Aluminum Extrusions

We have provided custom aluminum extrusions for a diverse set of industries since 1980. We specialize in low- to medium-production runs with a focus on quality, on-time delivery, and customer service. Our 14,400 sq. ft. facility handles both prototype and volume production runs.

Our production capabilities include:

- Press equipment: We operate a 550-ton RAM press and a 4.5-in. diameter press.

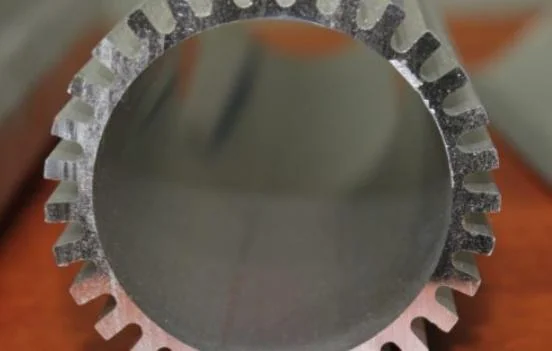

- Part specifications: Parts have to fit within a 4-in. diameter circle, and they must weigh less than 2.5 lbs./ft.

- Thickness and tolerances: We can achieve thicknesses down to 0.020 in. and standard tolerances within ±.005 in. For applications requiring additional precision, we can achieve special tolerances of ±.002 in.

- Common Aluminum Grades

Richardson Metals often works with two popular grades of aluminum:

- Aluminum 6061: This grade boasts good machinability, strength, formability, and weldability, making it a common choice for various aluminum extrusion applications.

- Aluminum 6063: Valued for its high-quality surface finishing properties, this grade offers an excellent mixture of extrudability and strength.

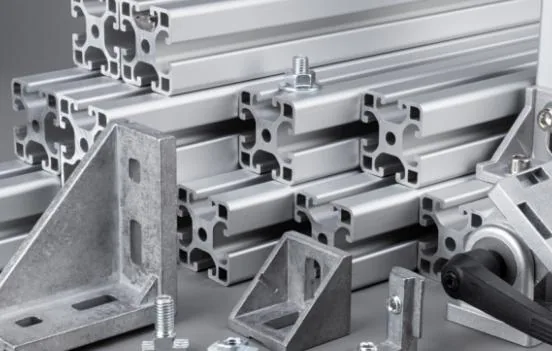

- Available Shapes

- Quality Control

Richardson Metals is an Aluminum Extruders Council (AEC) member, and we are committed to learning and sharing detailed information about extrusion technology, applications, and design with our customers and those in the engineering field. Our quality department offers optical comparisons, inspections, and certificates of conformance for all extrusions upon request.

Extruded Aluminum Shapes

Our facility is equipped to accommodate the following project specifications for extruded aluminum shapes:

- Material: 6061 and 6063 aluminum

- Shape: Hollow, semi-hollow, or solid components in bar, profile, rod, tube, and custom shapes

- Diameter: Up to 4 in.

- Weight: Less than 2.5 lbs./ft.

- Thickness: As low as 0.020 in. to tolerances of ±.005 in.

- Production volume: Prototype to production

- Extruded Aluminum Shape Options

- Value-Added Services

We offer an array of value-added services to deliver a fully finished part. These services include:

- CNC machining

- Deburring

- Cutting

- Drilling

- Engineering

- Prototyping

- Punching

- Specialized packaging

- Surface preparation and finishing

- Tapping

- Industries We Serve

We offer custom metal design and manufacturing solutions for a range of industries. These include:

- Construction

- Electronics

- Medical

- Aerospace

- Sports and recreation

- Telecommunications

Aluminum Machining Services

We operate two 3-axis CNC machines and one 4-axis CNC machine to create finished aluminum parts. Our in-house aluminum machining capabilities can minimize the number of setups, resulting in quicker delivery and a lower part cost. Our team can also offer finished or semi-finished parts to meet specific prototyping and production demands.

Machining Aluminum Alloys

A precipitation-hardened alloy, 6061 aluminum contains magnesium and silicon. It possesses great mechanical properties, has good weldability, and is one of the most commonly used alloys for general purposes.

The properties of 6061 aluminum alloy typically include:

- Easy anodization

- Excellent corrosion resistance to seawater and other atmospheric conditions

- Good surface finish

- Medium to high toughness and strength

- Good weldability

- Good workability

We can also provide custom extrusions to near-net tolerances, which can reduce the need for extensive machining.

Richardson Metals' Commitment to Industry-Leading Aluminum Services

Our commitment to offering industry-leading aluminum services allows us to serve as an ideal manufacturing partner for our customers. With four decades of industry experience, the Richardson Metals team applies its skill and insight to every project.

To learn more about our custom aluminum extrusions, extruded aluminum shapes, and aluminum machining services, contact us today. You can also request a quote for personalized assistance regarding your upcoming project.