The Benefits of Choosing Richardson Metals for Your Custom Aluminum Extrusion Needs

Comments Off on The Benefits of Choosing Richardson Metals for Your Custom Aluminum Extrusion NeedsRichardson Metals, Inc. is a trusted supplier of custom aluminum extrusions. We serve the aerospace, military, construction, medical, electronics, and other industries with low- to medium-volume production and on-time delivery. Learn more about us and our capabilities.

Expertise and Experience

Having reliable access to custom extruded aluminum shapes helps our customers drive innovation and bring new solutions to market across industries. Since 1980, our team has built a reputation for quality products and service. We continue to expand our knowledge and capabilities for custom aluminum extrusions.

Custom Solutions Tailored to Your Need

We extrude 6061 and 6063 aluminum with a 550-ton, 4.5 in. diameter RAM press. This means that extruded parts must fit within a 4 in. diameter and have a maximum weight less than 2.5 lb. per foot. We can produce extrusions as long as 20 ft., as thin as 0.002 in., and hold tolerances within ± .005 in. Our dies and equipment can produce a range of profiles including:

- Solid Shapes

- Hollow Shapes

- Semi-Hollow Shapes

- Rod/Bar

- Tubing

- Custom Shapes

Comprehensive Services From Start to Finish

Richardson Metals provides comprehensive extrusion and machining services including prototyping, full-scale production, and quality inspection.

Our in-house fabrication services include:

- Three- and four-axis CNC machining

- CNC milling

- Cutting

- Deburring

- Drilling

- Grinding

- Punching

- Tapping

In addition, we offer value-added finishing services that include anodizing, painting, silk screening, powder coating, laser etching, and polishing, for a complete manufacturing solution.

High-Quality Materials and Manufacturing Processes

Aluminum is valued for its high strength-to-weight ratio, along with its machinability. It is also relatively inexpensive and easily recycled. processes.

Materials

Most of our extrusions are made with the following:

- 6061 Aluminum: strong, machinable, formable, weldable.

- 6063 Aluminum: highly extrudable for complicated shapes and thin-walled hollows.

The Manufacturing Process

Custom aluminum extrusion is a multi-step process:

- Design and Engineering. Customers provide profile, dimension, and tolerance specifications, and our engineers analyze the design.

- Die Manufacturing. We create a precision die to extrude the profile.

- Extrusion. The aluminum billet is heated and forced through the die lengthwise, which causes the material to take the shape of the die as it is pushed through and out of the extrusion press.

- Post-processing. Additional processing, such as punching, cutting, machining, and finishing may be required based on the application.

- Quality Control. We inspect extrusions throughout the manufacturing process to ensure all requirements are met.

Strong Customer Focus

Since 1980, Richardson Metals, Inc. has been delivering reliable, high-quality custom aluminum extrusions for applications in many industries. We prioritize low to medium-production runs, maintaining a focus on customer care and delivery.

Contact the Experts at Richardson Metals, Inc.

Richardson Metals is known for exceptional extrusions, machining, and finishing work for customers in the aerospace, defense, medical, electronics, telecommunications, and other industries. Our team includes skilled die makers, experienced engineers, and knowledgeable sales and support staff who work hard to make each project a success.

Contact us to learn more about our custom aluminum extrusion capabilities, or request a quote today.

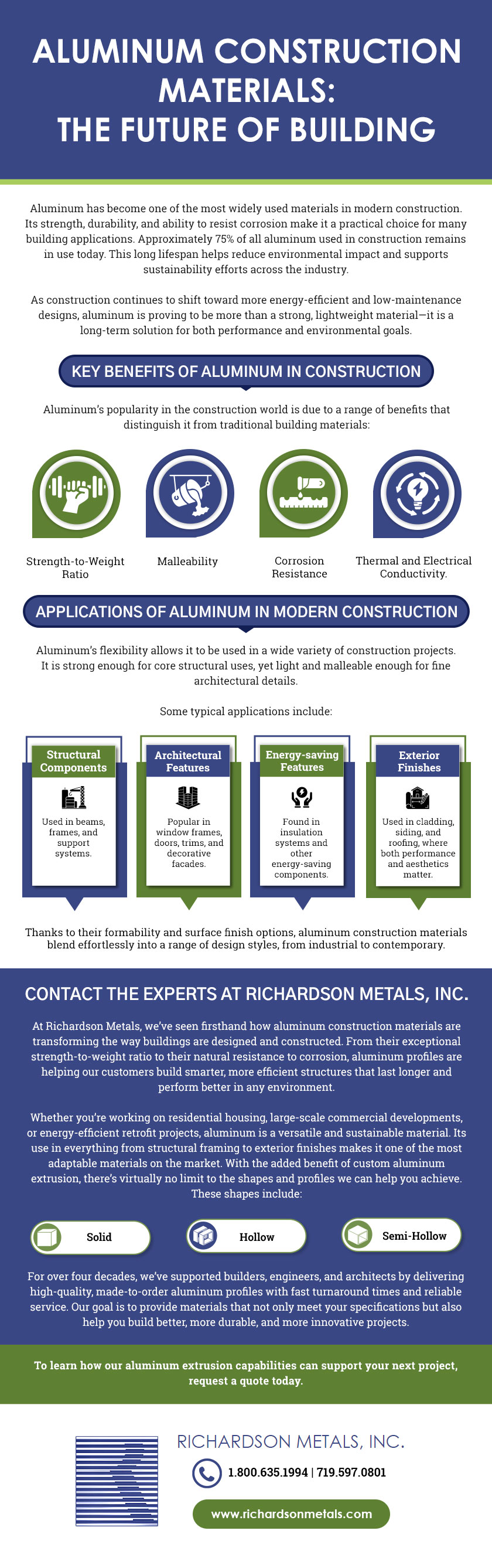

Aluminum Construction Materials: The Future of Building

Comments Off on Aluminum Construction Materials: The Future of BuildingAluminum has become one of the most widely used materials in modern construction. Its strength, durability, and ability to resist corrosion make it a practical choice for many building applications. Approximately 75% of all aluminum used in construction remains in use today. This long lifespan helps reduce environmental impact and supports sustainability efforts across the industry.

As construction continues to shift toward more energy-efficient and low-maintenance designs, aluminum is proving to be more than a strong, lightweight material—it is a long-term solution for both performance and environmental goals.

Key Benefits of Aluminum in Construction

Aluminum’s popularity in the construction world is due to a range of benefits that distinguish it from traditional building materials:

- Strength-to-weight ratio. Aluminum is approximately one-third the weight of steel, yet it still offers a substantial load-bearing capacity. This makes it ideal for buildings where both strength and low weight are necessary, such as multi-level structures or those with complex frameworks.

- Malleability. The metal is highly formable. When heated and pushed through a die, aluminum can take on nearly any shape. This process, known as extrusion, enables the metal to be used for both structural and decorative purposes.

- Corrosion resistance. Aluminum naturally develops a thin oxide layer that protects it from rust and decay. This makes it especially useful in outdoor construction, where rain, wind, and other elements can weaken other materials over time.

- Thermal and electrical conductivity. Aluminum is known for its ability to conduct heat and electricity efficiently. This makes it suitable for components like heat exchangers, window frames, and electrical wiring, which benefit from good thermal performance.

These advantages allow aluminum construction materials to deliver long-term value in everything from high-rises to energy-efficient homes.

Applications of Aluminum in Modern Construction

Aluminum’s flexibility allows it to be used in a wide variety of construction projects. It is strong enough for core structural uses, yet light and malleable enough for fine architectural details.

Some typical applications include:

- Structural components. Used in beams, frames, and support systems.

- Architectural features. Popular in window frames, doors, trims, and decorative facades.

- Energy-saving features. Found in insulation systems and other energy-saving components.

- Exterior finishes. Used in cladding, siding, and roofing, where both performance and aesthetics matter.

Thanks to their formability and surface finish options, aluminum construction materials blend effortlessly into a range of design styles, from industrial to contemporary.

Contact the Experts at Richardson Metals, Inc.

At Richardson Metals, we’ve seen firsthand how aluminum construction materials are transforming the way buildings are designed and constructed. From their exceptional strength-to-weight ratio to their natural resistance to corrosion, aluminum profiles are helping our customers build smarter, more efficient structures that last longer and perform better in any environment.

Whether you’re working on residential housing, large-scale commercial developments, or energy-efficient retrofit projects, aluminum is a versatile and sustainable material. Its use in everything from structural framing to exterior finishes makes it one of the most adaptable materials on the market. With the added benefit of custom aluminum extrusion, there’s virtually no limit to the shapes and profiles we can help you achieve. These shapes include:

- Solid

- Hollow

- Semi-hollow

For over four decades, we’ve supported builders, engineers, and architects by delivering high-quality, made-to-order aluminum profiles with fast turnaround times and reliable service. Our goal is to provide materials that not only meet your specifications but also help you build better, more durable, and more innovative projects.

To learn how our aluminum extrusion capabilities can support your next project, request a quote today.