Guide to 6061 Aluminum

Leave a CommentOne of the most important considerations when designing an industrial project is the materials involved. With metal alloys, it can be challenging to select the best option because there are so many.

Aluminum is a popular material for a wide range of industrial projects, with an equally vast range of alloys. Aluminum 6061 is one of the most versatile and durable alloys in use today. This guide will discuss the properties, benefits, applications, and types of aluminum 6061 that make it such a highly preferred material.

What Is Aluminum 6061?

Aluminum 6061, or 6061 aluminum, is the world’s most commonly used aluminum alloy. Its primary alloying elements are magnesium and silicon. Aluminum 6061’s heat treatability, easy machining, weldability, corrosion resistance, and strength are desirable properties for many applications. This alloy is also excellent for situations that require anodization, which adds a coating of anodic oxide to protect the metal.

Aluminum 6061 is commonly found in consumer products—bicycle frames, cameras, pins—as well as industrial products like marine hardware, decorative hardware, aircraft parts, couplings, electrical components, valves, and brake and hydraulic pistons.

Aluminum 6061 Benefits and Applications

Aluminum 6061 is also called structural aluminum for its strength in structural applications. Because it is a wrought alloy instead of a cast alloy, it possesses good mechanical properties that allow it to be rolled or forged into various standard and custom shapes. Anodization can add aesthetics, durability, and corrosion resistance to the metal surface.

The adaptability of 6061 aluminum has made it a standard material in these industries:

- Construction

- Sports and recreation

- Medical

- Electronics

- Telecommunications

- Aerospace

- Military

General Properties of 6061 and Common Types of 6061

Pure metals have fixed, limited properties, but aluminum 6061—an alloy of aluminum, magnesium, and silicon—combines the best properties of each element to produce a better metal. Magnesium increases strength, and silicon lowers the metal’s melting point. The hybrid material is stronger and more flexible, and it can be further adjusted to specific needs. The distinct elements of aluminum 6061 cannot be separated, giving it a strength that rivals steel.

There are two main tempers of 6061 aluminum: 6061-T4 and 6061-T6. Aluminum 6061-T4 is aged naturally, whereas aluminum 6061-T6 is aged artificially to enhance its strength.

All 6061 aluminum products have good corrosion resistance, machinability, weldability, and general workability. It is a medium to high strength metal alloy.

Working With Industry Leader Richardson Metals, Inc.

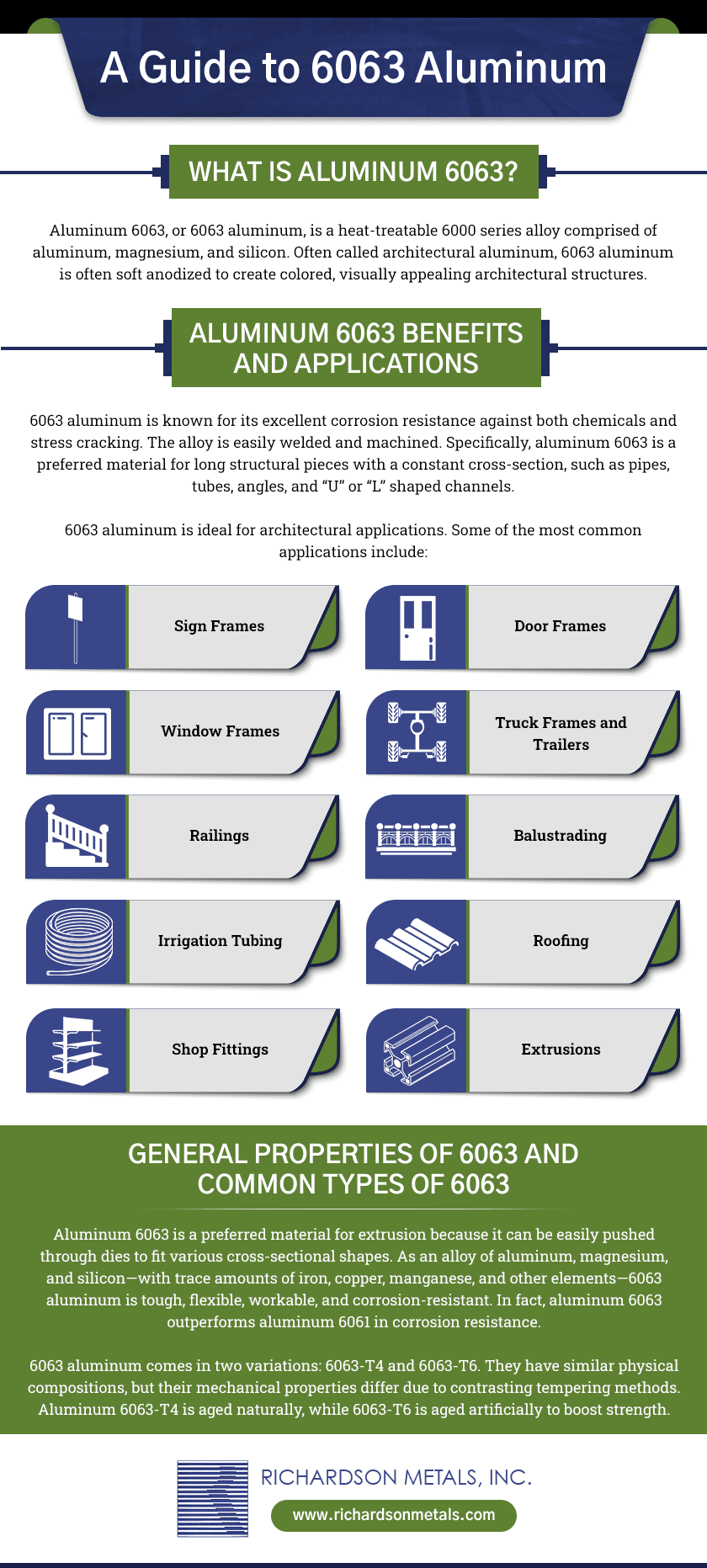

With over 50 years of experience, Richardson Metals has a reputation for providing stellar customer service in custom aluminum extrusions. Because we specialize in low to medium production runs of aluminum 6061 and aluminum 6063, we can deliver premium quality and highly specialized expertise to our customers.

Richardson Metals provides a one-stop shop for designing, engineering, producing, and inspecting services. We maintain stringent quality controls at every stage of the manufacturing process. Learn more about our services, or contact us to see how we can help with your next project.