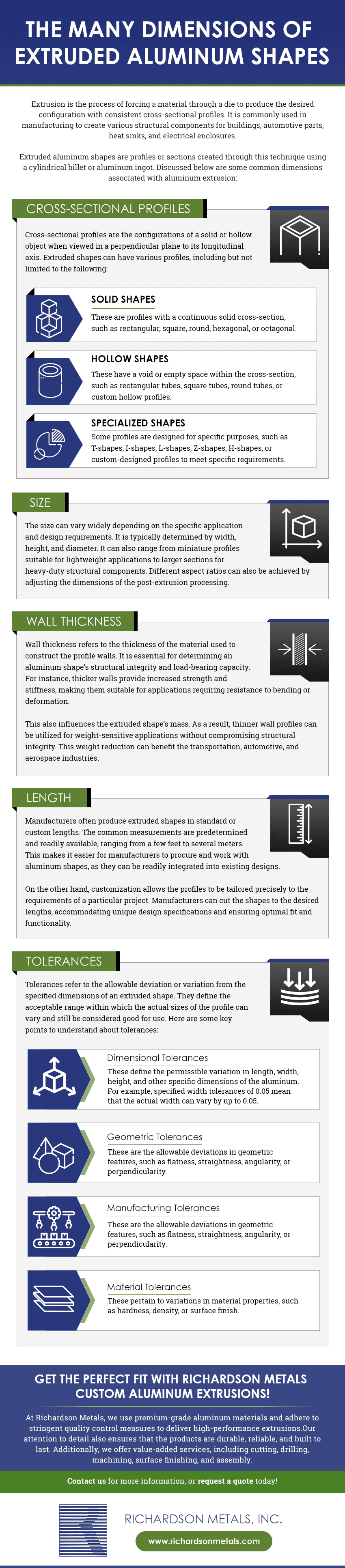

The Many Dimensions of Extruded Aluminum Shapes

Leave a CommentExtrusion is the process of forcing a material through a die to produce the desired configuration with consistent cross-sectional profiles. It is commonly used in manufacturing to create various structural components for buildings, automotive parts, heat sinks, and electrical enclosures.

Extruded aluminum shapes are profiles or sections created through this technique using a cylindrical billet or aluminum ingot. Discussed below are some common dimensions associated with aluminum extrusion:

1. Cross-Sectional Profiles

Cross-sectional profiles are the configurations of a solid or hollow object when viewed in a perpendicular plane to its longitudinal axis. Extruded shapes can have various profiles, including but not limited to the following:

- Solid shapes:These are profiles with a continuous solid cross-section, such as rectangular, square, round, hexagonal, or octagonal.

- Hollow shapes:These have a void or empty space within the cross-section, such as rectangular tubes, square tubes, round tubes, or custom hollow profiles.

- Specialized shapes:Some profiles are designed for specific purposes, such as T-shapes, I-shapes, L-shapes, Z-shapes, H-shapes, or custom-designed profiles to meet specific requirements.

2. Size

The size can vary widely depending on the specific application and design requirements. It is typically determined by width, height, and diameter. It can also range from miniature profiles suitable for lightweight applications to larger sections for heavy-duty structural components. Different aspect ratios can also be achieved by adjusting the dimensions of the post-extrusion processing.

3. Wall Thickness

Wall thickness refers to the thickness of the material used to construct the profile walls. It is essential for determining an aluminum shape’s structural integrity and load-bearing capacity. For instance, thicker walls provide increased strength and stiffness, making them suitable for applications requiring resistance to bending or deformation.

This also influences the extruded shape’s mass. As a result, thinner wall profiles can be utilized for weight-sensitive applications without compromising structural integrity. This weight reduction can benefit the transportation, automotive, and aerospace industries.

4. Length

Manufacturers often produce extruded shapes in standard or custom lengths. The common measurements are predetermined and readily available, ranging from a few feet to several meters. This makes it easier for manufacturers to procure and work with aluminum shapes, as they can be readily integrated into existing designs.

On the other hand, customization allows the profiles to be tailored precisely to the requirements of a particular project. Manufacturers can cut the shapes to the desired lengths, accommodating unique design specifications and ensuring optimal fit and functionality.

5. Tolerances

Tolerances refer to the allowable deviation or variation from the specified dimensions of an extruded shape. They define the acceptable range within which the actual sizes of the profile can vary and still be considered good for use. Here are some key points to understand about tolerances:

- Dimensional tolerances:These define the permissible variation in length, width, height, and other specific dimensions of the aluminum. For example, specified width tolerances of 0.05 mean that the actual width can vary by up to 0.05.

- Geometric tolerances: These are the allowable deviations in geometric features, such as flatness, straightness, angularity, or perpendicularity.

- Manufacturing tolerances:These account for variations introduced during the manufacturing process, including extrusion, cutting, and other fabrication operations.

- Material tolerances: These pertain to variations in material properties, such as hardness, density, or surface finish.

Get the Perfect Fit With Richardson Metals Custom Aluminum Extrusions!

At Richardson Metals, we use premium-grade aluminum materials and adhere to stringent quality control measures to deliver high-performance extrusions.Our attention to detail also ensures that the products are durable, reliable, and built to last. Additionally, we offer value-added services, including cutting, drilling, machining, surface finishing, and assembly.

Contact us today to learn more about our capabilities! You can also request a quote now.